Products

Contact Us

- Address:Suite 807, TianAn Hi-tech Development Plzaza. No.555 North PanYu Road, PanYu DistrictGuangZhou, China.

- Tel:020-39211238

- Fax:020-39211286

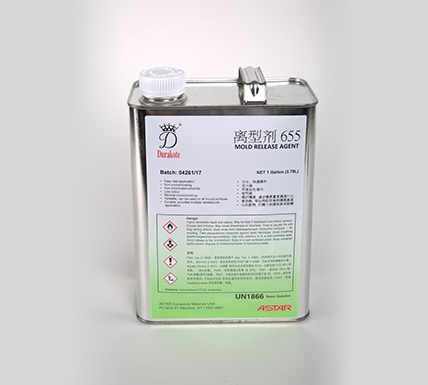

Durakote 655

Brands:Durakote

Types:

Field of application:

Introduction:Durakote 655 is designed to release all type of epoxy, phenolic, polyester (GRP) or vinly ester resins from steel, aluminium orcomposite moulds. Durakote 655 is an advanced polymeric resin in a fast drying non-chlorinated organic solvent blend. Durakote 655 is applied by a simple wipe-on technique; there is no need for rubbing or polishing. The Durakote 655 is extremely Durakote and capable of giving many releases per application. It will not contaminate the released surface.

|

Product Benefits |

Physical Properties |

|

l Easy ,fast application l Non contaminating l Non-chlorinated solvents l Low odour l Multiple mould build-up l Versatile, can be used on all mould surfaces l Durable; provides multiple release per application |

Appearance - Clear, colourless liquid Odour - Hydrocarbon Specific Gravity - 0.730 g/cc Solvent - Aliphatic hydrocarbon Coverage - 20-25 m2/L per coat Shelf Life - One year Storage - Flammable store(see MSDS) |

Note:

The polymeric resin used in Durakote 655 reacts with moisture. Please ensure can is resealed after use. Durakote 655 is supplied ready to use, no shaking or mixing is required. Do not mix with other products or solvents

For new, porous or damaged moulds, Durakote 615 should be used prior to applying the Durakote 655.See Durakote 615 technical date sheet for application details.

Application:

Please read Safety Date Sheet before use.

If necessary , polish mould to desired level of gloss. If a wax or silicone based release agent had been used, remove traces of wax using a solvent based cleaner such as Durakote PMC-600.Durakote 655 can be applied over existing semi-permanent release agents without a further cleaning step. However the mould should be clean and dry before use. Mould cleaning and release agent application should be performed in a well-ventilated area

1.Apply Durakote 655 to clean, dry cotton cloth.

2.Wipe wet cloth over mould surface covering an area of approximately 0.5 m2. Vigorous rubbing or polishing is not required..

3.Repeat steps 1 and 2 on the adjacent area, frequently reapplying the product to the cloth. Ensure a good overlap with the previous area to provide complete coverage

4.Repeat until mould is completely coated.

5.When dry, allow a further 15 minutes between coats for the film to cure.

6.Repeat step 1-5 above for a further 3 coats (4 in total)

7.When dry, allow final film to cure for at least 30minutes at room temperature before moulding. Allowing a longer cure or heat curing (e.g. 15 min at 60℃) will improve film durability.

Reapplication:

When the release becomes hesitant, reapply one coat of Durakote 655 in the same manner as described above.

Please contact us for further product and application information.

service

service Manager Du

Manager Du Hotline:

Hotline: